Cables, Connectors, and Screws (Oh My!): Improve Detection of Common Assembly Defects to Reduce Latent Failures

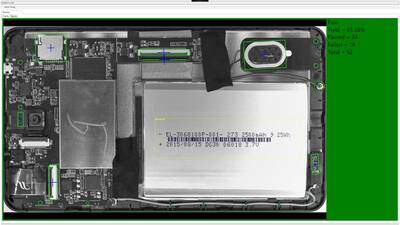

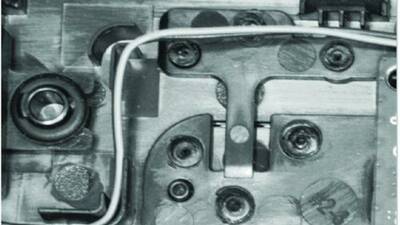

Photometry-based assembly verification performs better than typical machine vision or human inspectors when it comes to catching subtle defects in complex electromechanical assemblies, helping decrease your rate of escapes and latent product failures. Radiant’s INSPECT.assembly™ solution can detect and prevent misrouted cables, missing screws, or misaligned connectors that could pinch, detach, or loosen with use, resulting in failures after products ship.

In this technical note, you will learn:

- The benefit of photometry-based imaging systems for detecting subtle or subjective defects

- The impact of defects like misrouted cables, missing screws, and misaligned connectors

- Imaging specifications that enable Radiant's INSPECT.assembly to detect details in complex assemblies that can lead to product failures, even after devices pass functional test and other inspection processes

How can we help?

Please complete the following fields and we’ll follow up with you promptly.