As Display Technologies Surge Forward, New Display Measurement Solutions Keep Pace

This past week was the annual SID (The Society for Information Display) Display Week Symposium and Exhibition, returning live to Silicon Valley after two years of virtual events. Even though in-person gatherings were on hold in 2020-2021 due to the pandemic, this year’s exhibit shows there was no slowdown in research and development. Many advancements in display technology, device designs, and performance were in evidence.

SID Display Week 2022 Highlights

We spotlight a few of the many vivid and versatile displays at the show.

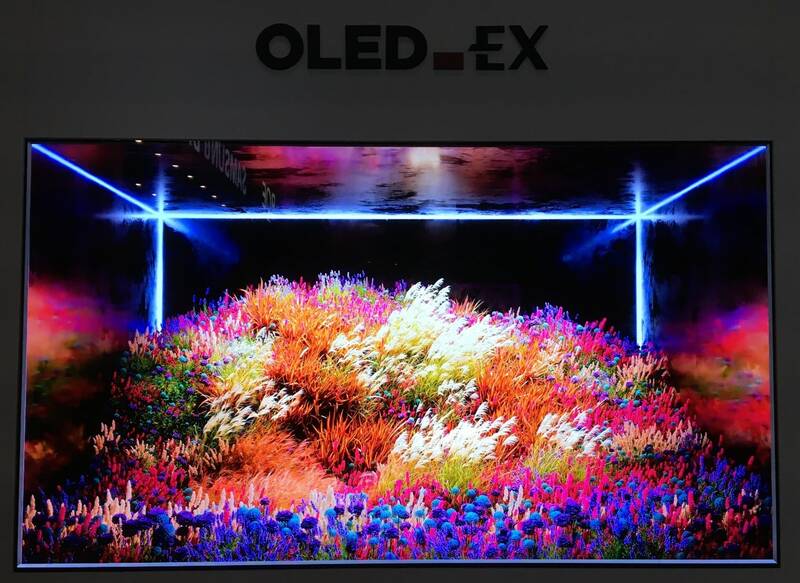

LG Display’s newest technology, the OLED.EX display, which uses deuterium (an isotope of hydrogen). The new tech provides increased brightness (up to 30% more according to the company), greater energy efficiency, and emits less of the blue light that can negatively impact human viewers. LG showed a 97” OLED.EX television with 3840 x 2160 resolution (4K), 500 / 200 nit luminance (APL 25 / 100%), and 99% color gamut.

LG Display’s 97” OLED.EX television.

There were many stunning quantum-dot displays at the show (using both QD filter and QD conversion layer methods), including Samsung’s 65” QD-Display.

Samsung’s 65” QD-Display.

BOE’s video wall featured its latest P.09 COG AM MLED display that uses a mini-LED backlight. The display is made from 20,736 Mini LEDs directly mounted to a glass backplane and features 2,304 local dimming zones and brightness of 1,500 nits.

BOE’s mini-LED backlit screen. (Image credit: TrendForce)

While big screens captured attention throughout the show, some of the most impressive displays were tiny, like the OLED microdisplay from eMagin—a 2K XL 2048 x 2048 screen with 2731 ppi— and the microLED microdisplay from PlayNitride with 1920 x 1080 (FHD) resolution and 4536 ppi.

Taking a peek at eMagin’s OLED microdisplay (left) and PlayNitride’s microLED microdisplay (right), although my cellphone camera doesn’t capture that the text was perfectly readable.

The centerpiece of Samsung’s booth was their ECO2 OLED displays. The company’s commitment to the planet encompasses device operation (a special polarizer layer reduces power consumption by about 25%), components (the device designs use less plastic), and packaging—Samsung has reduced the amount of product packaging material overall and replaced much of the non-renewable plastic items with paper and molded pulp packaging.

Samsung’s latest Galaxy foldable phones use its power-friendly Eco2 OLED display technology.

Also from Samsung comes a new bendable OLED gaming monitor. This 42” monitor can be a flat screen for watching movies, or, with the touch of a button, curve in for an optimal gaming experience. It offers resolution of 3840 x 2160 (105 pixels per inch), a 120 Hz refresh rate, and 0.1 ms (GTG) response time. curvature range of up to 1,000R, or a radius of 1,000mm

Samsung’s 42” bendable OLED with adaptable curvature: from flat screen viewing to curved for an exciting gaming experience. (Image: Source)

Of course, there was no shortage of foldable smart phones and other flexible displays, such as LG’s 8-inch 360-degree Foldable OLED, Samsung’s Flex G flexible display, which folds inwards twice, and the Flex S, that can fold both inwards and outwards, and BOE’s collection of “f-OLED” displays that fold, flex and roll, and AUO’s double-sided 5.6-inch rollable display.

A two-sided, rollable microLED display from AUO. (Image: Source)

A shiny new Mercedes EQS 450 was parked on the expo center floor showing off its full-width dashboard called the MBUX Hyperscreen. The screen integrates three displays behind curved cover glass to merge seamlessly into a panel more than 141 cm (56 inches).

The three displays are a 12.3-inch LCD with direct-matrix backlight for the instrument cluster, a 17.7-inch corner-cut plastic OLED for the center stack display, and a 12.3-inch plastic OLED display for the front passenger. It also integrates diver monitoring (DMS) technology including an infrared stereo camera, illumination, and face and eye tracking systems located in the LCD notch area.

The Mercedes Benz MBUX Hyperscreen.

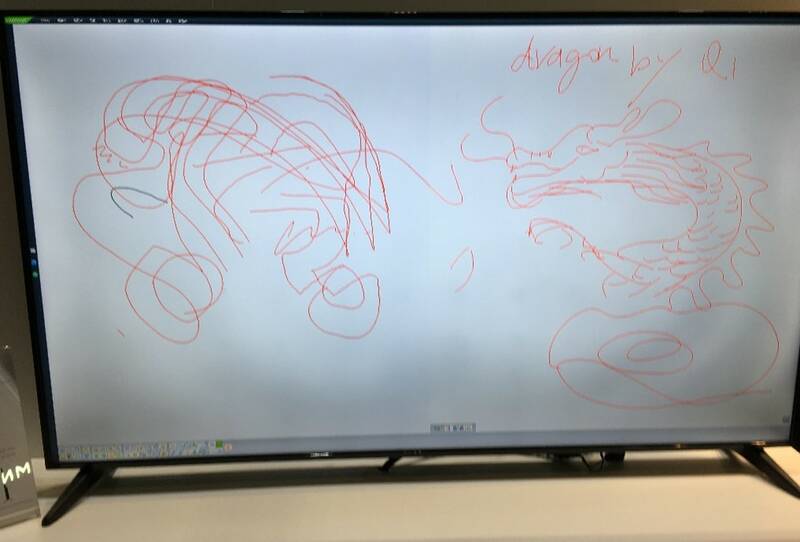

Touchscreens were in evidence everywhere at the show. Most notable was the 65” UD touch on Pol (polarized film) display from TCL CSOT (China Star Optoelectronics). It’s not only a conventional display, but also a touch-responsive panel that users can draw on with a finger or stylus. In display mode, it has 3840 RGB x 2160 resolution and a 4000:1 contrast ratio.

Many show visitors enjoyed scribbling on this 65” touchscreen from TCL CSOT.

New Display Devices Demand New Measurement Systems

As consumer expectations continue to rise, smart phones makers continue to offer new folding and flexible devices, and the television industry continues its progression to higher and higher display resolution (and smaller and smaller image elements such as microLEDs and quantum dots), manufacturers need new solutions for quality inspection and measurement.

The pace of growth in AR/MR and near-eye displays (NED) likewise demands more versatile quality inspection solutions. And the acceleration of display integrations in vehicles and growth in overall display device production around the globe means manufacturers need to keep increasing both efficiency and yields.

Radiant’s R&D teams have been busy developing new display metrology solutions to meet these needs. Three of our new solutions were on display at the SID event, for XR device measurement, small character color measurement, and a new system that povides fast, accurate spectral and spatial display measurement.

Radiant at SID Display Week 2022.

XRE Lens Provides Flexibility for Near Eye Display Measurement

Fundamentally, replicating the human visual experience has continued to drive the optical design of XR test systems. But the diversity of XR devices and their measurement requirements continue to expand. New display types, fields of view (FOV), resolutions, focal distances, form factors, and unique combinations of these elements can’t be addressed universally with a single optical solution.

Many manufacturers opt for custom measurement/optical solutions, which carry a significant time and cost burden, and which are not easy to deploy. Radiant’s new XRE Lens helps headset makers begin to address the diversity in XR optical designs and reduce the need for costly custom measurement equipment design cycles. The XRE Lens solution provides manufacturers with several specification options and flexible features to meet unique measurement parameters.

The XRE Lens uses patent-pending technology that features electronic focus and configuration options, offering flexibility for evaluating visual elements as they are seen through the headset and simplifying the task of deploying measurement for a diverse array of AR, VR, and MR devices. The lens pairs with high-resolution ProMetric® imaging colorimeters and photometers and TT-ARVR™ Software to provide a complete automated visual inspection solution for XR display testing in R&D and production.

The XRE Lens is the first commercial imaging metrology solution to offer electronic focus for in-headset XR display testing. Electronic focus allows precise focal distances to be set and adjusted remotely via software to measure multiple or variable focal planes. Electronic focus also enables automatic focus changes as part of fully automated visual inspection routines, optimizing testing efficiency and supporting advanced analysis.

For example, through-focus MTF analysis requires the system to iterate through a series of focus distances to find best focus for multiple regions across a display. A complete analysis could require thirty or more focus adjustments. Using a manual lens, these settings are imprecise and time-consuming—potentially taking hours for a complete analysis with little confidence in the accuracy of the result. With electronic focus, a through-focus MTF analysis can be fully automated to provide results in a matter of seconds.

To provide additional flexibility, the XRE Lens is available in two configurations—folded or non-folded—to achieve the appropriate near-eye measurement position within different headset form factors. The folded (“periscope”) geometry can be applied to measure devices with head straps or other headgear that prevent a linear path to the near-eye measurement position. A folded configuration also supports dual-eye (stereoscopic) measurement, where two XRE Lens systems are positioned inside the headset at once to capture simultaneous measurements of left- and right-eye positions.

The XRE-Lens' electronic focus makes it easy to perform a fully automated through-focus MTF analysis in a matter of seconds.

Both folded and non-folded lens configurations pair with either the ProMetric Y Imaging Photometer for luminance-only measurement or the ProMetric I Imaging Colorimeter for measuring values of luminance and chromaticity. Manufacturers can choose from 29-, 45-, and 61-megapixel resolution options to maximize imaging precision over the solution’s ±35° (70° total) angular field of view.

High-Resolution, High-Accuracy Color Measurement of Marked Text and Symbols

Many products sold today must display markings such as text, logos, symbols, and numbers for identification, traceability, regulatory compliance, user information, and branding. Typically, these markings are applied to the surface of product components during the manufacturing and assembly process. Components can be made of metal, plastic, glass, ceramic, or other materials and marked using laser etching, printing, or similar methods. Product makers must ensure that these markings are legible, correctly formed, and meet color specifications.

To inspect markings, manufacturers typically use multiple methods. Machine vision cameras can perform text inspection and area measurement—but they can’t measure color accurately according to universal standards. So additionally, some combination of spectrometers and human inspectors is needed to do color measurements. Using multiple methods for quality inspection increases the time, cost, and effort required.

With Radiant’s new ACIS™ (Area Color Inspection System) solution, manufacturers can now meet both inspection needs in a single solution. Leveraging the visual acuity and context of Radiant’s imaging colorimetry systems, ACIS provides inspection of text and symbol formation, size, and positioning, while simultaneously taking quantitative color measurements (e.g., CIE L*a*b*) with accuracy and repeatability.

Used in a lab or on the production line, ACIS enables electronic product manufacturers to improve quality while increasing efficiency. The system performs fast, automated measurement of text and symbol shape (inclusions and exclusions), dimensions, color, and contrast. ACIS helps manufacturers to ensure characters are legible and correctly formed, verify compliance with requirements for CE and other regulatory markings, ensure brand color and quality standards are met, perform product text validation, and support part traceability (e.g., confirming serial numbers).

The ACIS solution integrates a high-resolution ProMetric® I-series Imaging Colorimeter with a proprietary illumination configuration, mounted in a metal framework. Completing the solution is ACIS software, which combines colorimetric measurement with sophisticated image analysis for accurate color and quality inspection.

Spectral and Spatial Data with New Two-in-One Measurement Solution

In 2009, Radiant Vision Systems invented the first direct integration of a colorimetric imaging system with a spectrometer for acquiring two sets of data from the same light input (US Patent No. 8482652). At the time, this solution added capability to Radiant’s Source Imaging Goniometer® (SIG) for highly accurate, three-dimensional light source modeling.

Beyond the near-field measurement data provided by the SIG’s internal ProMetric Imaging Colorimeter, spectral data (power vs. wavelength) could be acquired by the spectrometer for applications such as calculating a color rendering index (CRI). The invention used mirrors and fiber optic connectivity built into the imaging system to allow both systems to measure data from the same point and angle relative to the light source at the same time—near-field measurements (via the imaging system) and spectral data (via the spectrometer).

The combination of imaging and spectral data is similarly useful for other light and color measurement applications—for instance, understanding the output of an illuminated display or elements within an augmented or virtual reality (AR, VR) headset. In these scenarios, if imaging systems and spectrometers are applied separately, manufacturers must source and purchase both systems and can only apply one system at a time for measurement, requiring multiple stations or processes.

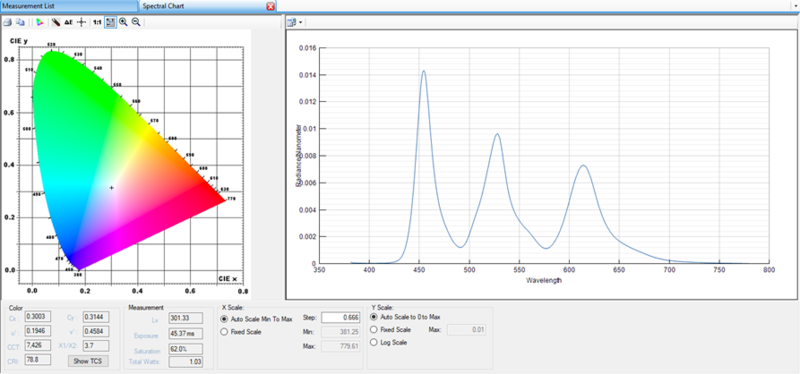

In situations where product makers need both spectral data and spatial measurement device qualification, Radiant’s new ProMetric® I-SC Solution for light and color measurement offers our customers both capabilities in one system. Combining the functions of an enhanced ProMetric I Imaging Colorimeter from Radiant with a CAS 140D spectroradiometer from Instrument Systems GmbH on a single platform, the ProMetric I-SC Solution enables efficient measurement of both spectral data and image-based colorimetric data with complete data capture, analysis, output, and calibration functions controlled through a central software interface.

Using Radiant’s patented technology, the ProMetric I-SC applies a polarization-insensitive mirror to enable direct integration of a ProMetric I Imaging Colorimeter and a CAS 140D spectroradiometer. This integrated solution captures two pieces of a complete measurement at once: the CAS 140D measures highly accurate correlated color temperature (CCT) and color rendering index (CRI) while Radiant’s high-resolution ProMetric I61 (61-megapixel) Imaging Colorimeter measures precise luminance (cd/m2) and chromaticity (CIE xy or u’v’) data for all points in an image—including regions as small as a display subpixel.

Because all components of the measurement system are designed together, there is no need to purchase multiple pieces of equipment or learn separate platforms to implement a complete solution. All data is captured at once with the convenience of one system, eliminating system repositioning, movement, downtime, and risk of error during manual system alignment or data transfer.

The ProMetric I-SC leverages advantages of Radiant’s ProMetric I Imaging Colorimeter. For example, we can apply the solution with associated optics like Radiant’s AR/VR Lens, which not only captures full-FOV measurement images within headsets but now places the spectral measurement point inside the headset via the imaging system’s optics.

Manufacturers can easily measure spectral and spatial data, monitor spectral output, and directly apply data for color calibration if needed, without moving the measurement system from the intended near-eye position. Imaging also enables visualization of the spectral measurement point and field of view in physical space (either x,y coordinates or angular degrees within the context of AR/VR headsets). This point is indicated in the software interface as a circle or rectangle on the measurement image.

Through direct integration, the ProMetric I-SC also facilitates calibration of the connected imaging colorimeter for measuring new devices or device states (i.e., a different color on a display or backlit component). A calibration function can be initiated as needed to capture and apply spectral data from the spectrometer to align the imaging colorimeter’s response to standard CIE color-matching functions for highly accurate, repeatable measurement of a source.

With the ProMetric I-SC, Radiant provides a single measurement solution for spectral data capture, real-time calibration, and accurate imaging colorimetry.

This calibration function can be run on demand or programmed to run with each measurement as part of a fully automated visual inspection routine in TrueTest™ Software. From the TrueTest interface, users can control functions of both spectrometer and imaging colorimeter, initiate calibrations, view the spectral measurement point, and apply a comprehensive library of analyses for test and measurement. Users can also use TrueTest to view data captured by the integrated spectrometer as chromaticity coordinates in the CIE 1931 color space and as a spectral plot.

These latest products add to Radiant’s already extensive portfolio of visual inspection and metrology solutions, including high-resolution imaging systems, specialty lenses, and software. For 30 years we’ve been helping the leaders in lighting, display, automotive, and consumer device manufacturing to increase product quality, manufacturing yields, and customer satisfaction. We look forward to helping enable the next generation of high-quality displays, sure to be on exhibit at next year’s Display Week!

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List