Extra Credit: Getting More Out of Black Mura Standard Testing

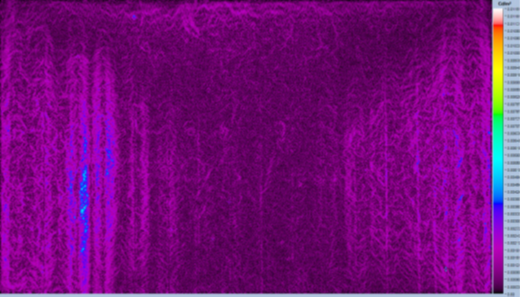

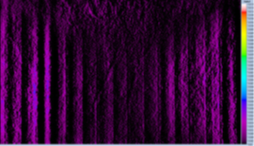

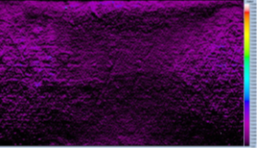

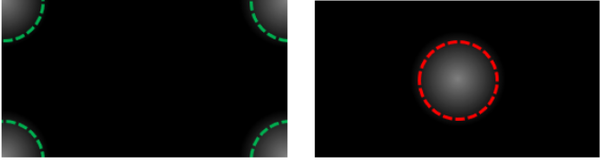

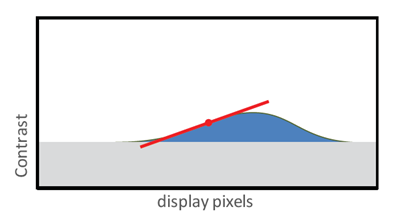

Black Mura as analyzed by a Radiant imaging colorimeter and TrueTest™ Software. Black Mura image (top); gradient in Y-direction (bottom left); gradient in X-direction (bottom right).

Radiant ProMetric® Imaging Colorimeters paired with TrueTest™ Software have been employed for Black Mura standard testing for many years. Radiant has even documented the steps to show how to set up and apply our equipment for Black Mura testing to ensure display uniformity per the German Automotive OEM Work Group and DFF’s specifications.

But there is more to achieving a quality display than checking off the basic requirements—like improving measurement efficiency, accuracy, testing completeness, and additional competitive advantages. These are some of the benefits that Radiant’s technology is able to provide quite seamlessly. What’s more: Radiant’s camera and software solution provides Black Mura standard testing in addition to comprehensive display tests for color, luminance, contrast, high-resolution pixel & sub-pixel defects, view angle, and more, all from a single system. Let’s take a look at some of the areas Radiant provides some “extra credit” for display testing beyond standard Black Mura analysis…

Radiant Advantages for Black Mura Standard Testing

- Evaluation Based on Mura Type

Basic Requirement: Black Mura standard testing prescribes a method for identifying mura based on non-uniform spatial regions with values below a given uniformity percentage.

Extra Credit: Not all mura is created equal. As a display manufacturer or OEM, you understand that certain manifestations of non-uniformity may have more of an impact to display quality than others, depending on their shape, position, or size. Radiant TrueTest Software is able to differentiate between various mura types for more comprehensive mura analysis. The software’s TrueMURA™ module includes specific algorithms for each type of mura present in a display, allowing manufacturers to perform pass/fail on different kinds of defects. TrueMURA tests for:

- Black Mura

- Blob Analysis

- Butterfly Mura

- Corner Light

- Diagonal Line Mura

- Edge Mura

- LED Mura

- Line Mura

- Random Mura

- Spot Mura

Different types of mura, identified using the same measurement conditions for Black Mura Standard, can be passed and failed differently based on their type. Learn more: Mura and Defect Detection with TrueTest

- Evaluation Based on Mura Severity

Basic Requirement: Black Mura standard testing specifies a tolerance of 80% uniformity on white test image, and 50% on black image for all areas across the display.

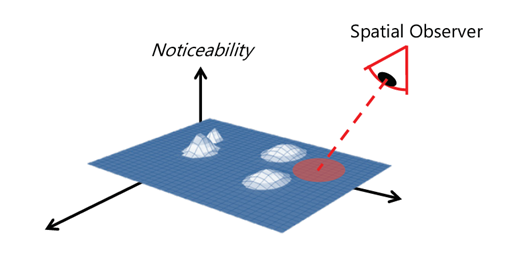

Extra Credit: Radiant TrueTest offers a method for not only identifying types of mura, but for grading mura severity based on type. This feature allows manufacturers to set pass/fail parameters for certain types of mura—when present—if they exceed a set tolerance based on human noticeability values. This is made possible using algorithms that compute JND (“Just Noticeable Differences”), a detection algorithm based on U.S. patent 7,783,130, “Spatial Standard Observer” (SSO) technology, which is licensed by Radiant from the National Aeronautics and Space Administration (NASA).

Areas of non-uniformity in the center of the display may be more of a distraction to users than defects toward the edges or corners of a display. For this reason, you may be interested in going beyond Black Mura requirements to grade these manifestations of mura with different severity. For instance, internal quality standards may be set for tolerances of 90-100% uniformity for Spot Mura that appears in the display center, while 80% uniformity for Edge Mura may suffice.

- Gradient Filter

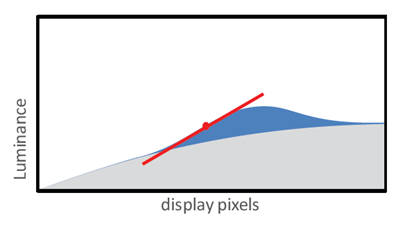

Basic Requirement: Black Mura standard testing requires analysis of display uniformity and gradient relative to a white or black test image.

Uniformity defects Gradient defects

Extra Credit: Different test methods and images are employed to analyze areas of non-uniformity, versus those used to analyze the effects of gradient. Display gradient—a common issue in displays (image above, right)—can cause unreliability in uniformity measurement data, adding anomalous visible defects that must be taken into account when measuring non-uniform regions (image above, left). To improve measurement accuracy of these regions, TrueTest Software offers a Gradient Filter feature that normalizes broad gradient changes across the display. This is automatically applied to images before mura testing to ensure that broadscale gradient is not a factor of a local uniformity calculations.

No filter; testing mura and background gradient.

With TrueTest Gradient Filter, testing mura only.

- Register Active Display Area

Basic Requirement: Black Mura standard testing relies on the elimination of moiré patterns for accurate mura testing.

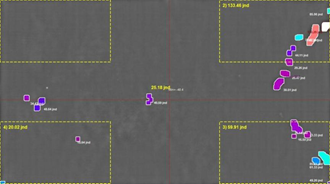

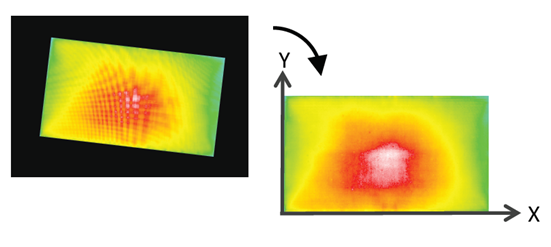

Extra Credit: Refraction of light through display layers that causes effects like moiré (interference in the form of conflicting sets of lines on the display) is largely affected by display angle. For this reason, orientation of the measurement system relative to the display during testing may be deliberately misaligned to prevent such moiré effects. Consequences of adjusting for an optimal display orientation or position are: a) the display may appear rotated outside of the rectangular analysis area of the imaging system, or b) negative space may result around the display within the imaging area. This can reduce the accuracy and speed of image analysis. Radiant’s TrueTest Software applies automatic registration of the active display area (called RADA), which rotates and crops the image of the display area for efficient image processing. RADA accounts for necessary or unintentional display rotations by dynamically locating the corner pixel locations in the display and automatically defining the precise measurement area of the image at normalized x,y positions.

- Automatic Moiré Removal: Dynamic Filtering

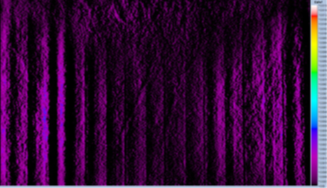

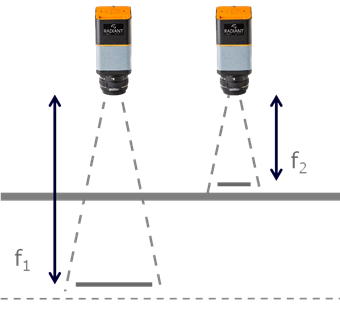

Basic Requirement: Black Mura standard testing recommends moiré removal by defocusing the image.

Extra Credit: Image defocusing causes blurring of the image and can lead to inconsistencies in the measurement system’s ability to identify and grade the severity of mura in the display. Defocusing also prevents additional high-resolution testing for defects like dead pixels and lines, which as a requirement must not be present at the time of Black Mura standard testing. TrueTest Software offers Dynamic Filtering, which automatically removes moiré effects while preserving a sharp image for analysis, enabling high-resolution testing before or after mura analysis.

Moiré removal by defocusing (left) versus automatic moiré removal by TrueTest Software’s Dynamic Filtering.

- Automatic Moiré Removal: Electronic Lens

Basic Requirement: Black Mura standard testing recommends moiré removal by defocusing the image.

Extra Credit: Using electronically-controlled lenses, Radiant’s ProMetric imaging systems can be defocused to achieve the Black Mura testing standard of 50-90% modulation depth percentage to remove moiré from the scene through image blurring. TrueTest can apply the correct Black Mura algorithm and sequence to the blurred image for testing to Black Mura standard requirements. Afterward, electronic lenses can quickly be adjusted through software to automatically set the correct focus and aperture of the lens to look for high-resolution defects like stuck on/off pixels, bright spots, line defects, surface defects, and other issues.

-

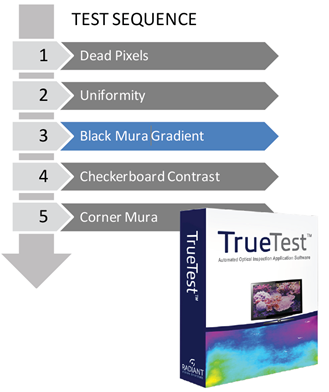

Test Sequencing for Multiple Analyses

Basic Requirement: Black Mura standard testing is usually only part of more elaborate display tests defined by internal standards or other governing bodies.

Extra Credit: Beyond Black Mura, display testing at your facility may include overall luminance, color, dead pixels, line defects, checkerboard contrast, distortion, focus uniformity, points of interest, additional types of mura, and a range of other tests. TrueTest Software offers these tests and more within a test sequencing framework, allowing manufacturers to apply one test at a time, or multiple tests in a series. Using TrueTest API, a Radiant display test system can be integrated to control test images on the display and

synchronize these images with steps in a TrueTest test sequence for fully-automated analysis.

With minimal setup, a Radiant display test system can be applied for Black Mura standard testing (and beyond) with advantages in efficiency and accuracy. To learn the step-by-step Radiant method for meeting DFF display test requirements, and benefits of a TrueTest system, read our Technical Note: “Testing for Black Mura Gradient Per German Automotive (DFF) Standards.”

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List