The Glass Cockpit Takes Flight: Evaluating Aircraft Display Quality

In the early days of aviation, pilots relied on purely analog cockpit instrumentation, typically consisting of a handful of dials and gauges to track the aircraft’s operational status and perform navigation. In fact, even in the 1950’s planes such as the Boeing 707 still had a clear overhead dome so crew could use the stars to assist with navigation.

With the invention of the CRT display and the introduction of computerization and digitization in aviation, aircraft makers began to incorporate screens into the cockpit. For example, in 1991 “Boeing moved from an analogue (conventional) cockpit with gauges and dials on the 747-300 to a computerized cockpit for the 747-400 with eight-inch Cathode Ray Tube (CRTs) displays. The result was the elimination of 600 dials and gauges.”1

Since the 1980s, more and more display screens have been making their way into aircraft as new technologies such as LCD displays provide crisper and brighter images. The development of digital avionics systems has increased dramatically, in parallel to the increase in displays and computerized systems in automobiles. These trends have given rise to the term “glass cockpit” to characterize newer aircraft that contain a cluster of display screens.

Many of the dials, gauges and controls in a traditional analog cockpit (left) have now been digitized and incorporated onto display screens in the new glass cockpit (right).

Displays can show a wealth of information that once would have required multiple individual gauges and dials, making them lighter than traditional instrumentation.

“Glass cockpits integrate avionics systems, navigation databases, and flight management systems into a seamless interface, offering pilots unprecedented levels of automation and efficiency. Advanced features such as synthetic vision, terrain awareness, and weather radar integration further enhance safety and decision-making capabilities in all phases of flight.”2

The glass cockpit is credited with enhancing accuracy, safety, situational awareness, and efficiency for pilots. Encompassing primary flight displays, multi-function, back-up, and mission displays, the glass cockpit market now stands at $1.9 billion as of 2022, with growth of 4.5% CAGR predicted to 2032 to reach $3.0 billion.3

It’s common in the history of aviation for the military to lead the way, and the glass cockpit is no exception: “Military aircraft are using multi-functional displays more frequently as a result of the advantages they offer to pilots. Contemporary military aircraft cockpits contain all-glass, complex multi displays to enhance video and imaging capabilities. This allows pilots to view a variety of video sources, including outward monitor processing units and multimedia sensors. These include cameras, satellite tracking, infrared sensors, and armaments depending on their needs.”4

The modern cockpit of a military helicopter shows the proliferation of display screens, all encased in ruggedized casings to withstand potentially harsh flight and battle conditions.

Bringing Display Metrology to the Cockpit

More display screens in the cockpit means more need for display quality inspection and measurement. For years, traditional analog cockpits relied primarily on backlit symbols and instruments. Radiant solutions such as VIP™ (Vision Inspection Pack) has helped aircraft companies to measure and assess the quality of backlit cockpit panels. But the new glass cockpits present an entirely new set of visual inspection challenges. Instead of individual backlit characters, all of the letters, numbers, symbols, maps, and images are now presented on display screens, integrated and overlaid. Instead of backlit panels, many airplane makers are now having to adopt display metrology techniques to inspect and measure the quality and performance of cockpit screens.

Examples of the detailed images and information displayed on cockpit screens that must be readable at a glance by pilots during live flight.

As with almost any aspect of the highly regulated aviation industry, the FAA has issued requirements and recommendations to ensure cockpit display quality and safety, encompassed in 14 CFR and associated Advisory Circulars such as AC 150/5190-7, AC 20-175, and more. Industry organizations such as the General Aviation Manufacturers Association (GAMA) provide guidance for aircraft makers, such as in their Publication #12 “Recommended Practices and Guidelines for an Integrated Flightdeck/Cockpit in a 14 CFR Part 23 (or equivalent) Certificated Airplane.”

Quality & Safety of Cockpit Displays

Radiant has decades of experience helping display makers to achieve quality goals and document their compliance with regulatory requirements. We’re helping designers and manufacturers of cockpit displays to meet visual performance requirements for color, contrast, resolution, brightness, and focus. Using Radiant’s ProMetric® Imaging Photometers and Colorimeters, display makers can ensure that information is displayed clearly and consistently, under all ambient lighting situations and operating conditions.

Radiant provides complete camera-and-software solutions to evaluate LCD flat screens, curved and free-form shaped displays, and head-up (HUD) displays in the aircraft. Our TrueTest™ Software automates multiple tests for luminance, chromaticity, uniformity, clarity and contrast, identifying defects such as dead pixels that can detract from a display’s visual accuracy and performance. The software also enables display makers to evaluate and correct “sparkle” (interference caused by anti-glare coatings), and our TT-HUD™ module provides tests to characterize head-up display projections on screens and in helmets.

Of course, the quality of the display panels in the cockpit can only do so much to ensure aircraft safety. The other critical aspect of safety is “human factors” – how pilots interact with the displays; studies have shown the importance of training on these new digital systems to achieve the promise of increased flight safety. Nevertheless, manufacturers who apply Radiant’s display measurement and inspection solutions can ensure that one challenge pilots won’t have to contend with in the air is poor visual displays, helping them carry crew and passengers safely to their destination.

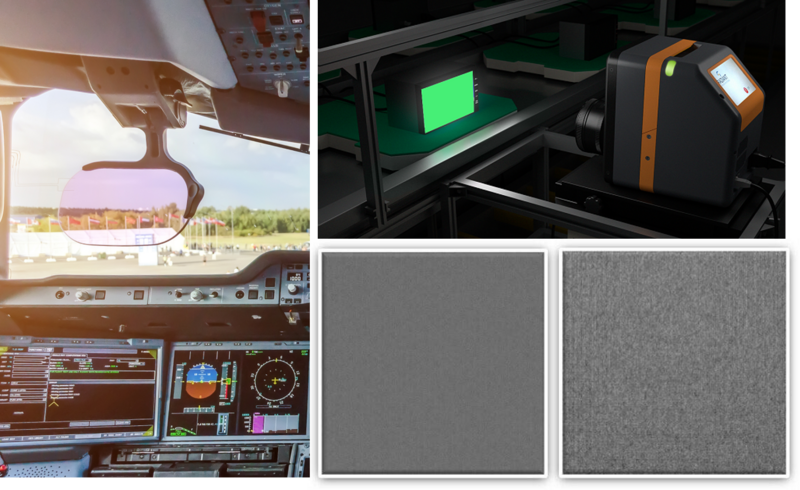

Radiant provides quality measurement solutions for aviation displays including flat panel screens and HUDs. Our ProMetric® Imaging Photometers and Colorimeters pair with TrueTest™ Software to provide automated, precise measurement of brightness and color, defects, uniformity, sparkle, HUD projection distortions and ghosting, and more. Lower left image shows the effect of an anti-glare film applied to a display, causing distortions and a speckled effect.

CITATIONS

- “How have airline cockpits changed over the decades,” Airline Ratings, February 20, 2017.

- “Advancements in Cockpit Technology: From Analog to Glass Cockpits,” AVI-8/The Aviation Journal. (Accessed July 24, 2024.)

- Glass Cockpit Market Outlook (2022 – 2032), Persistence Market Research, March 2023.

- Ibid.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List