Innovative LED Applications Require Precision Luminance and Chromaticity Measurement

LEDs (light emitting diodes) were first developed and commercialized in the 1960s. Since then, they have become common in applications such as displays (both direct-view and as backlights), replacing incandescent and CFL light bulbs in homes and offices, for streetlights, and for dynamic holiday light displays. The global LED market was valued at US$57.5 billion in 2020 and is projected to nearly triple in size by 2027, reaching $151.02 billion in revenues.1

The popularity of LEDs is attributable to several factors: their ability to provide bright illumination with up to 75% lower energy consumption than incandescent lighting2 (compared to just 20-35% energy savings from CFL bulbs3), their flexibility/tunability to provide virtually any color or SPD wavelength profile to meet a variety of specialized and smart lighting needs, and their longer lifespan. As LED production costs and market prices continue to trend downward, more and more industrial, commercial, and consumer users are adopting LEDs.

New LED Applications

LED-based products have long been able to display a range of colors by grouping small red, green, and blue LEDs together. More recently, however, developers have been able to create multi-colored LEDs—a single encapsulation that contains all three primary colors.

Monochrome blue, red, and green LEDs (left) and a multicolor LED (right).

Designers and developers in multiple fields have been taking advantage of LED capabilities to create new applications and play with light effects using this versatile technology, including:

Wearables – Because LEDs can be very small and consume little power, fashion designers are finding ways to incorporate them into textiles and clothing. Some pieces incorporate a tiny battery pack and remote control.

LED matrix hoodie from Lumen Couture (left) and an LED-infused wedding dress by Luminous Clothing (right). (Images: © Lumen Couture and © Luminous Clothing)

Faux Neon – Sign makers are using LEDs to replace lighted elements that would previously have been made from neon tubing. While many people still appreciate the aesthetics of neon, LEDs can be run with lower voltage, increasing safety and reducing power usage. They are also more durable than neon in outdoor applications that are exposed to the weather.4 Municipal zoning rules about energy efficiency and evolving UL standards are an incentive for many neon applications to transition to LEDs.

LED lighting replacing neon in outdoor signage for a Florida restaurant chain. (Image source)

LED Light Strips – Now widely available and affordable, LED light strips are enabling home decorators, product designers, and DIY consumers to incorporate lighting effects into a vast range of items. They are being used for everything from mood lighting to art installations, customized task lighting to night-time safety.

LED light strips can be easily applied to emphasize architectural elements (upper left), create mood lighting (upper right), illuminate workspaces (lower left), and keep pedestrians, dogs, and cyclists safe on the streets at night (lower right). (Lower images source)

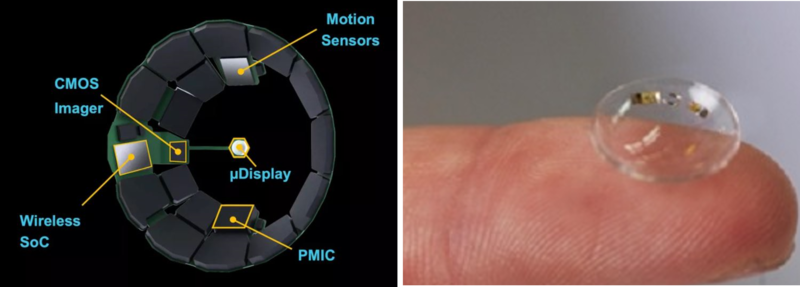

Contact Lenses – LED contact lenses first emerged about a decade ago, but recent developments are in the realm of “smart lenses”. Some developers are creating contact lenses that replace the function of augmented reality smart glasses, displaying information for the wearer. Meanwhile medical researchers have developed lenses that can monitor a wearer’s diabetes by measuring glucose levels in tears5—they use a tiny LED light to signal the wearer if readings become too high or low—and some that can even treat retinopathy.6

Smart contact lenses from Mojo (left) that act like miniature augmented reality smart glasses, and smart lenses embedded with sensors and LEDs to monitor glucose levels in diabetics (right). (Image sources: left and right)

The Need for Light Source Testing

These are just a few examples of innovative LED applications. Before LEDs and lighting products reach the market, however, significant research, development, and testing goes on behind the scenes. Manufacturers of LEDs and luminaires must ensure that products not only provide the brightness (luminance) and color (chromaticity) performance that users expect, but that LED products also comply with industry safety regulations and standards such as:

- Underwriters Laboratory, such as UL 8750

- CE and RoHS certification in the European Union

- Illumination Engineering Society, such as ANSI/IES LM-79-19

- And other similar organizations and certification standards around the globe.

Obtaining Measurement Data for LEDs and Small Light Sources

For 30 years, Radiant has provided solutions for measuring luminance, chromaticity, and other characteristics of light sources. One of the company’s very first products was a goniometric measurement system to capture light source data from multiple angles. Now in its fourth generation, Radiant’s SIG-400 (Source Imaging Goniometer®) is a fully automated, computer-controlled goniometric system designed to meet the needs of LED researchers, developers, manufacturers, and users by providing LED die and device characterization.

The SIG-400 precisely measures near-field luminous intensity for LEDs and other small light sources. It captures and aggregates images and flux measurements from thousands of angular viewpoints around a light source to precisely characterize the source's near-field output in three dimensions. The SIG-400 also supports measurement of vertically oriented light sources and can be used with both microscope and extended-field-of-view optics, thus providing the flexibility to measure both LEDs and other light sources.

The automated, computer-controlled arm on the SIG-400 rotates a ProMetric® Imaging Photometer around an LED to capture thousands of angular viewpoints for precise characterization of near-field output in three dimensions.

The SIG-400 uses a ProMetric® I Imaging Colorimeter which is rotated around the LED to capture images used to generate highly accurate near-field models. This data can be used directly to investigate the performance of the LED, or it can be exported using Radiant Vision Systems ProSource® Software, for use in all major optical design software packages. The SIG-400 solution offers:

- Modeling of the complete spatial and angular output of a light source

- Approximately 1,500 measurements to output a complete light source characterization

- Automated motion and image capture control

- Scan set-up checklist with quick links to software features for ease of use, and completely configurable scan resolution

- Real-time, on-screen visualization of luminance measurement images, with playback option

- A record of ambient alignment images, operating conditions, and product info for sample

- Near field and far field luminous intensity distributions

- Data visualization tools: cross section, 2D isoplot, 3D isoplot, CIE color chart plot

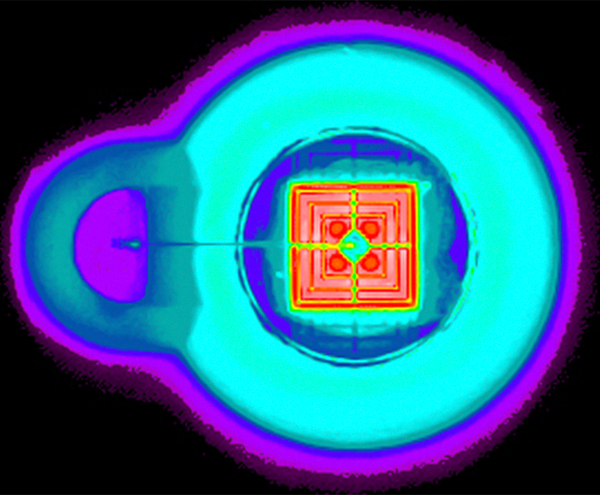

An example of SIG-400 system imaging results of a light source, shown in false-color scale.

The SIG-400 also requires limited measurement space (<5m) and can be used to extrapolate far-field distribution (or ray-traced) data from Radiant Source Model™ (RSM) files. The system can generate ray set data to quickly output IES, EULUMDAT (LDT), and RSM files—or luminance data for measuring Unified Glare Rating (UGR). These IES, LDT, and RSM files can be exported into common optical design ray-tracing software (such as ASAP®, FRED®, LightTools®, LucidShape®, Opticad®, OSLO®, OpticStudio™ (ZEMAX), SimuLux®, SPEOS®, TracePro®, Photopia™, and IES TM-25).

To learn more about how to obtain source imaging data needed for product engineering, quality control, and lighting design, read the How-To Guide: “Capturing Measurement Data for Lighting Design: LEDs and Small Light Sources.”

CITATIONS

- “LED Lighting Market Size to Surpass Around US$ 151.02 Bn by 2027.” Precedence Research, June 22, 2021, as reported on Global Newswire.

- “LED Lighting.” US Department of Energy (Retrieved December 9, 2021).

- “The Great Debate: LEDs vs CFL Bulbs.” Payless Power, July 9, 2018.

- Peters, L., “Color me LED.” Signs of the Times: 2021 LED Trends, February 2, 2021

- "Korean Researchers Develop Contact Lens that Diagnoses Diabetes." Korea Bizwire, January 26, 2019=8

- “Smart LED Contact Lens Diagnoses Diabetes & Treats Retinopathy.” Medical Product Outsourcing, January 13, 2020.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List