Are We Close to a MicroLED Market Breakthrough?

Since the release of the first microLED television in 2012, there's been a lot of interest and attention paid to the technology. Nevertheless, it seems like microLED displays have been creeping towards commercialization at a glacial pace. Over the last decade, Radiant has been tracking the progress of this technology, and now offers more solutions than ever for accurate and efficient quality inspection, measurement, and correction of nano-scale microLED pixels and subpixels.

The State of MicroLEDs

At CES 2024, the massive consumer electronics show held every year in Las Vegas, there were more microLED products and prototypes on display than ever before. Could the technology finally be on the cusp of breaking through to the mass market? Industry analysts at Yole don't think we're quite there yet, but they are predicting commercial production within 2-3 years, and broad market adoption in another 5-10 years.1

Many industry experts see wearables and AR/VR microdisplays as the hot spot for microLEDs. DSCC forecasts that smart watches will take the lead in unit sales by 2026,2 with releases from several big brands anticipated in the next year or so. MicroLED displays are energy efficient, durable, and offer superior brightness, making them attractive for AR/MR smartglasses and for automotive displays, which both have to retain visbility even in bright sunlight.

MicroLEDs have also found a place in the premium (some might say ultra-premium) television market, ever since 2018 when Samsung debuted its 146-inch microLED screen, The Wall. Brands such as LG, Sony, Konka, and others have followed suit with more large-format microLED televisions and giant modular display screens.

MicroLEDs Take the Stage at CES 2024

Here's a wrap-up of microLED trends and some of the exciting new devices featured at CES: Right out of the gate, Samsung wowed the industry and media with its newest transparent microLED display:

In automotive, Continental showed a unique transparent microLED display embedded in a Swarovski crystal frame that appears to float in front of the dashboard.

Continental's Crystal Center Display (Image © Continental)

AUO also made a splash with it's microLED automotive displays including a dashboard and a touch-screen transparent microLED display on the passenger window:

AUO's pillar-to-pillar microLED dashboard display (left) and touchscreen window display (right). (Images © AUO)

In the AR/VR space, companies such as VuReal, Micledi, and Raysolve showed prototype microLED microdisplays. Chinese start-up Sitan previewed a miniscule (0.13") microLED display module featuring 10,000 psi.

Sitan microLED display modules at scale. (Image © Sitan Technology)

Managing Quality for MicroLED Displays

As exciting as all these micro elements may be, they can pose major quality headaches. One of the main factors that has slowed commercialization of microLEDs is how to achieve quality and minimize defects in the fabrication and mass transfer processes. Due to the size and density typical of microLED displays, traditional display inspection techniques are no longer sufficient. Unlike LCD displays that rely on a backlight, microLED and microOLEDs are individual emitters: each LED is its own pixel driven individually to emit its own light. This means microLEDs/microOLEDs can exhibit wider variation in birghtness and color from one pixel—or subpixel—to the next.

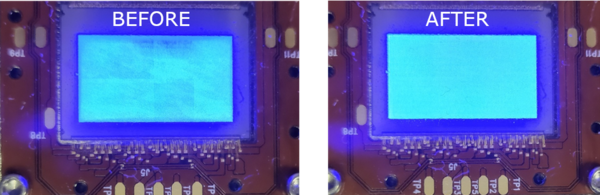

Defects and a lack of uniformity (called mura) need to be identified and measured accurately during the manufacturing process, which then enables a correction factor to be applied. The correction process (demura), helps improve the quality of a display so that it meets brand standards and can be sold instead of discarded. Inspecting high-PPD, high-resolution microdisplays down to the subpixel level requires very high-resolution measurement systems, such as Radiant's ProMetric® imaging photometers and colorimeters.

A microLED display shown before (left) and after (right) demura measurement and correction with a ProMetric imager and TrueTest™ software. (Images courtesy of Jasper Display.)

Radiant has developed solutions for accurate and efficient inspection of microLEDs at the wafer, panel, and device assembly / final QA stages of production. To learn more about the quality challenges of microLEDs and different approaches to measure and correct these displays, attend the upcoming GlobalSpec webinar: The Challenge of Emissive Display Uniformity: OLED & MicroLED Test and Correction. Presented by Radiant's Chris Williamson on January 31, the webinar will explain how demura (correction) of emissive displays can be accomplished, enabling microLED manufacturers to improve quality and increase yields. Key takeaways:

- Understand display quality challenges of newer OLED, microLED, microOLED, and other emissive displays

- Examine how new display metrology methods can detect mura (blemishes) at the individual pixel and subpixel level of OLED and microLED

- Learn the process of demura to correct emissive display defects and see examples of advanced metrology systems with advantages for demura.

Register for the Webinar

CITATIONS

- Mertens, R., "Yole sees significant microLED production in 2-3 years, with broader adoption in 5-10 years," MicroLED-Info, November 16, 2023.

- MicroLED Display Technology and Market Outlook, Report from DSCC, November 2023.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List