Tech Tip: Using Points of Interest to Meet International Headlamp Standards

The automotive industry is one of the most regulated industries in the world. In order to keep up with the increasingly strict safety standards, manufacturers are in need of equipment with higher accuracy than ever before. One such area of the industry standards that has been notoriously tedious to keep up with is the measurement and characterization of car headlamp intensity. For example, IIHS rates vehicles for Headlight Evaluation as part of their highway safety research and communications. Recently in 2016, the IIHS evaluated 31 midsize cars for acceptability of headlight intensity and found that only one model earned a good rating, with nine deemed marginally acceptable (read the press release). With these results communicated widely throughout the industry, and to consumers, automotive manufacturers are faced with negative brand implications if they do not improve their standing. Testing is certainly a priority in lamp design and manufacture, but with headlamps casting such an expansive beam of light, optimizing and controlling test methods and environments can be challenging.

Headlamp standards require a headlamp to emit a specific amount of light, in a specific direction, to produce a specific beam pattern. The headlamp beam is projected from a known distance onto a flat surface, illuminance measurements are taken at physical locations along the plane of the wall. In the past, a common method used to measure these points was using a handheld illuminance meter to manually test each point on the wall. This process is tedious, and not efficient for measuring many headlamps in a row. However, Radiant Vision Systems offers a much simpler solution that speeds up the process of measurement by capturing and evaluating all test points at once.

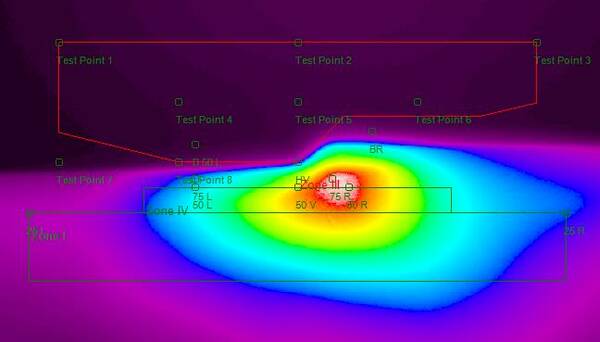

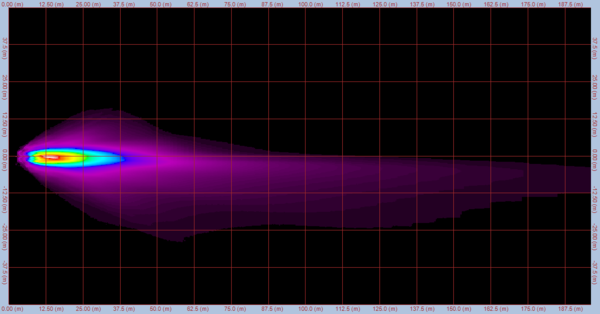

Using Radiant’s “Points of Interest” tool in our ProMetric® Software, combined with a high-resolution ProMetric I-series Imaging Colorimeter, automotive manufacturers and suppliers can easily measure an entire headlamp beam distribution in a matter of seconds. Radiant’s cameras can take both illuminance and luminous intensity measurements on a Lambertian wall, allowing customers to meet a variety of industry standards in a single testing environment, using a single system. Below is a sample measurement of the full beam distribution of a car headlamp, as captured in ProMetric Software and viewed in false color.

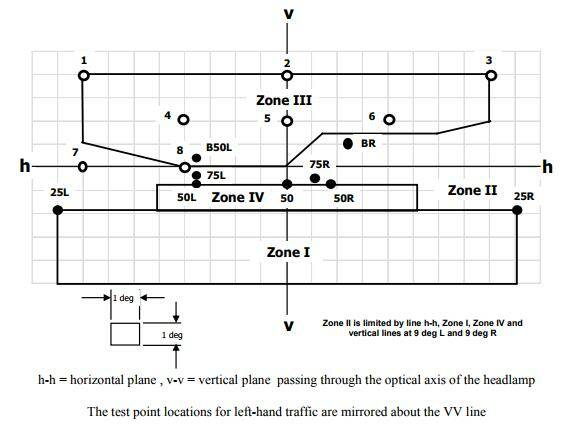

Using the Points of Interest tool, the user can create virtual detectors that report out intensity and color values at every point. Points of Interest, or POI for short, can be drawn in many different shapes, such as circles, rectangles, and polygons. Thanks to this flexibility, the software enables the user to create points of interest that mimic the test points required by international standards. For instance, below is an image of the ECE R112 headlamp standard. To test to this standard using Radiant measurement tools, the user could easily place POI in the ProMetric interface at the exact points (1, 2, 3, and so on) prescribed here.

The Points of Interest tool even allows the user to input exact special coordinates to place detectors at the same locations as the test points defined in the standard above.

The tool also allows the user to draw more complicated shapes, such as the polygon shape indicated for Zone III. Using the various POI shapes in ProMetric Software, the R112 standard can be mimicked exactly.

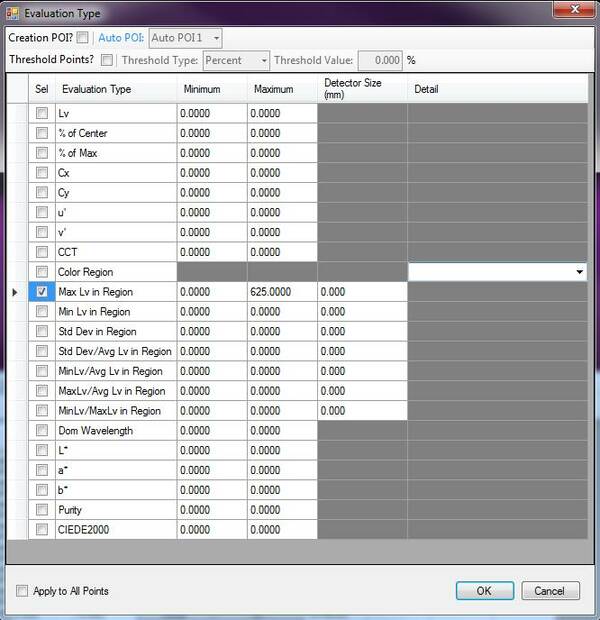

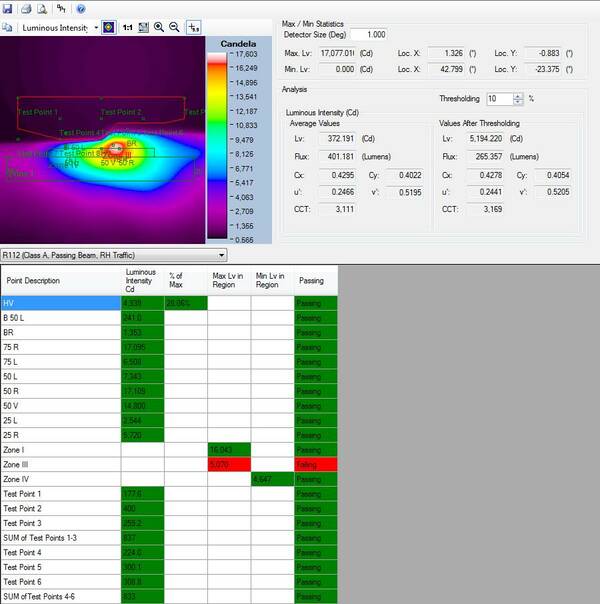

Each of these points can be configured with Pass/Fail criteria that can be used to quickly determine whether a headlamp meets a given standard, or needs to be adjusted or rejected. By default, ProMetric Software reports passing in green and the failing measurements in red. Below is an example of the criteria set for Zone III in the R112 POIs.

A maximum intensity threshold of 625 candelas was set for Zone III. Because an area within Zone III exceeded this threshold, it failed the criteria and was colored red.

ProMetric software also allows users to generate reports with all of the POI data, providing a convenient and easy to read format for quality checks.

Radiant’s ProMetric PM-HL™ software package for headlamp measurements currently comes standard with POI presets for ECE R20, ECE R112, ECE R123, and FMVSS108. However, POI can easily be created by any user to match other measurement standards. Also included in the PM-HL package is the Road Illumination tool and the Gradient POI tool. The Road Illumination tool allows the creation of a synthetic bird’s-eye-view of a headlamp projected on a road, as seen below.

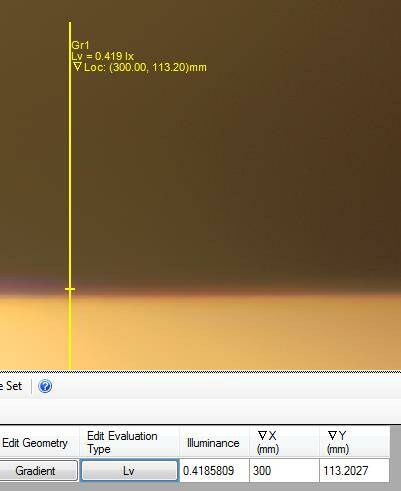

The Gradient POI tool, also shown below, allows the user to find the maximum gradient along a defined line.

With this specialized toolset for headlamp measurement, along with imaging systems capable of capturing all data points for evaluation, automotive manufacturers are more equipped than ever to meet headlamp standards with speed and ease. Here at Radiant, we’re happy to be a part of boosting headlamp rankings across the industry by leveraging our ProMetric product family.

For more information on Radiant Vision Systems' automotive solutions, visit our Automotive page, or contact us at Info@RadiantVS.com.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List